Last month, the U.S. Senate passed the CHIPS Act to boost domestic semiconductor production with $280 billion in subsidies and tax credits. Companies like Intel, TSMC, and Global Foundries would be able to access funding that will be used to build new, U.S.-based manufacturing facilities, train a new workforce to run these new foundries, and support related research.

The bill is a direct response to the colossal manufacturing and supply chain issues caused by the pandemic, which saw many industries grind to a halt after semiconductor companies were forced to slow down production, in turn causing shortages for all products with even the smallest electronic component, including phones, PCs, and cars.

What does the CHIPS Act mean for Enterprise Mobility?

Not much will change for small business and enterprise. Why? Because the CHIPS Act fails to address the entire downstream process of electronics design, development, and manufacturing – something we at Social Mobile live and breathe every day.

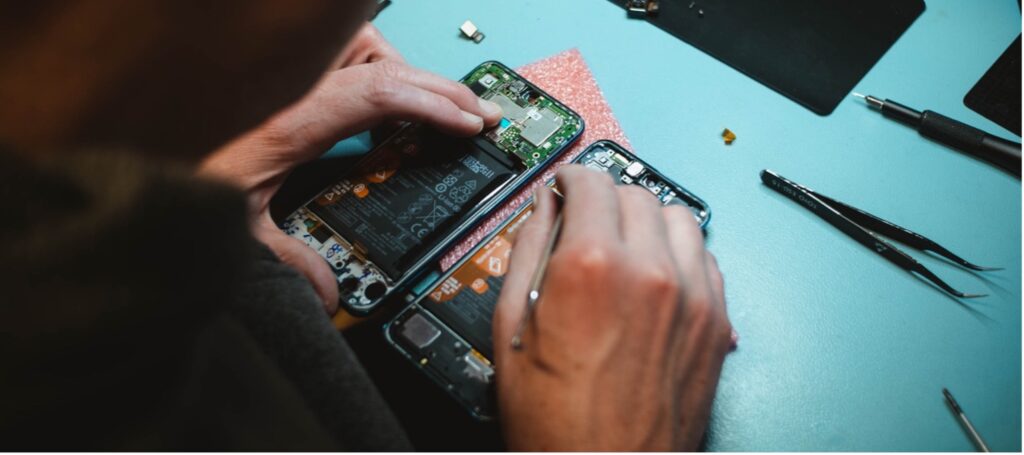

Yes, semiconductors are critical to any electronic device; however, what many fail to understand is that there are, on average, hundreds of components used in the production of each device. Touchscreens. Batteries. Speakers. Sensors. The list goes on.

Each one of these hundreds of components also need to be manufactured and brought to a factory where the device is assembled. Today, the vast majority of these components are manufactured abroad – mostly in Asia.

So what real benefit is there to US companies if we manufacture semiconductors domestically, only to ship them back overseas so our phones and PCs can be assembled, and then shipped back to the U.S. for the consumer? How will that prevent another supply chain disaster in the future?

What the government needs to do to fix downstream production in the U.S.

Policymakers need to look at this problem now and commit to a plan that enables U.S. companies to design, assemble, and manufacture devices within the U.S.

Constructing a fab (semiconductor fabrication facility) is an immensely complex and lengthy endeavor, and there are only a handful of groups who have successfully done so. In practical terms, it will take 3-5 years for the CHIPS Act to have a positive impact. That gives us a window to create another act that will deliver funding and tax incentives to build up a robust domestic supply chain for mobile devices and all other ancillary components.

Other nations that have been successful in their reshoring efforts have been able to bring both government and private enterprise to the table together. I’d welcome a meeting with my state representatives, like Florida governor Ron DeSantis, to talk about how companies like Social Mobile, a company born and bred in Florida, can help ensure the U.S. has stable and steady production capabilities for now and the future.

Recent Comments